INITIATIVES FOR THE GLOBAL ENVIRONMENT

Three Initiatives For Environment Protection

KAIHARA strives to produce the best quality denim without sacrificing our environment. Based on SDGs, we have set three initiatives for the environment pillar: "Clean Wastewater," "Conserving Resources," and "Clean Air". Here, we introduce some of our ongoing efforts and commitments.

01 Clean Wastewater

To achieve zero pollution to water source, membrane bioreactor (MBR) is installed in all facilities. Chemical oxygen demand (COD), one of the key water quality parameters, has been reduced over 70%, which is at the same level as the water source.

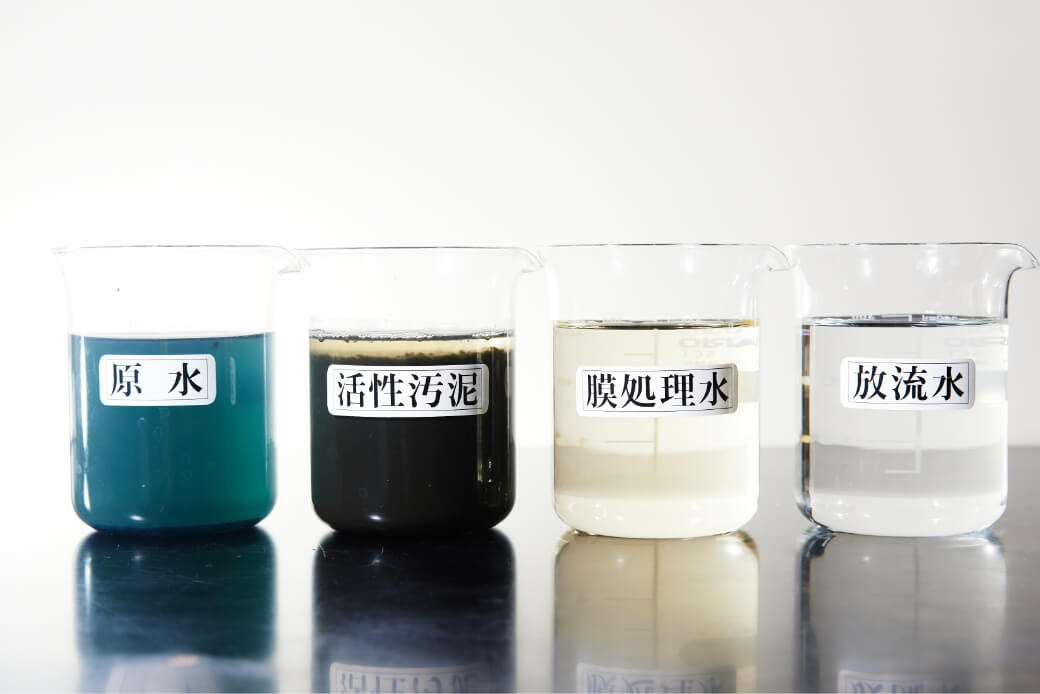

The samples from left to right are untreated wastewater, activated sludge containing microorganisms that decompose pollutants, membrane treated water after a series of filtration, and discharged water decolorized by ozonation. The introduction of membrane bioreactor (MBR) can remove all contaminants and produce effluent of high quality enough to be discharged to waterways.

02 Conserving Resources

About 5% of cotton regards as "cotton waste", which is not made into products because of immovable impurities. At KAIHARA, half of the cotton waste can be recycled, and the balance is effectively used as compost.

Waste yarns and fabric scraps are produced during the manufacturing processes. To minimize the production waste, we give a second life to these textile waste by recycling and upcycling to create new products.

03 Clean Air

With the completion of installation of high-efficiency boilers in all facilities in 2018, KAIHARA has reduced the energy consumption by 18% based on a defined production capacity.

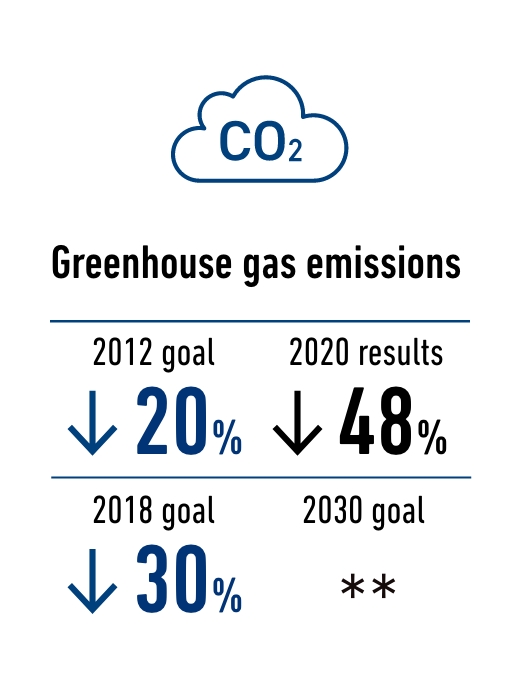

In order to reduce CO2 emission, we have been switching from fluorescent to LED lighting, the current installation rate is about 80%. About 5,000 tons of CO2 emission is reduced per year with the use of high-efficiency boilers and LED lighting.

Sanwa Factory acts as a pioneer in solar panel installation and started self-sufficiency in renewable energy. We are also implementing this system to other factories. We are also purchasing green energy.

Along with the introduction of high-efficiency boilers, we have switched to use LNG・LPG (Liquefied Natural Gas / Liquefied Petroleum Gas) as a cleaner energy source. All facilities have achieved zero sulfur oxide (SOx) emissions since 2019.

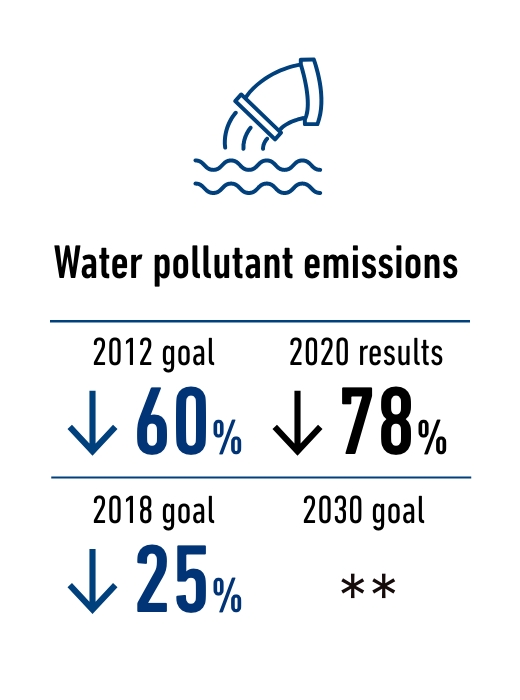

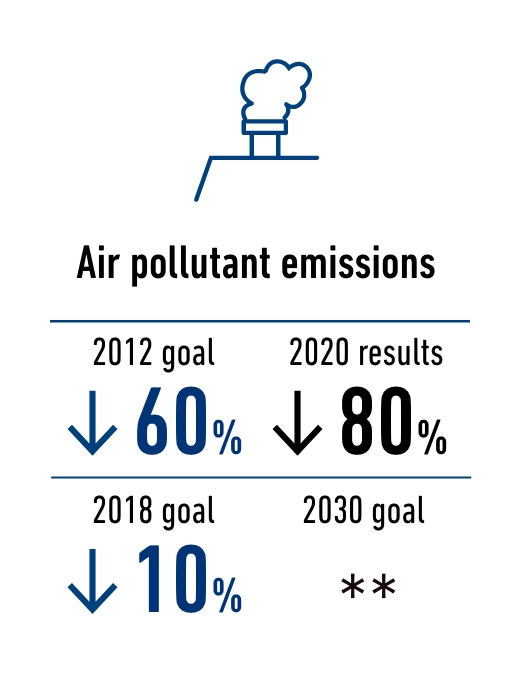

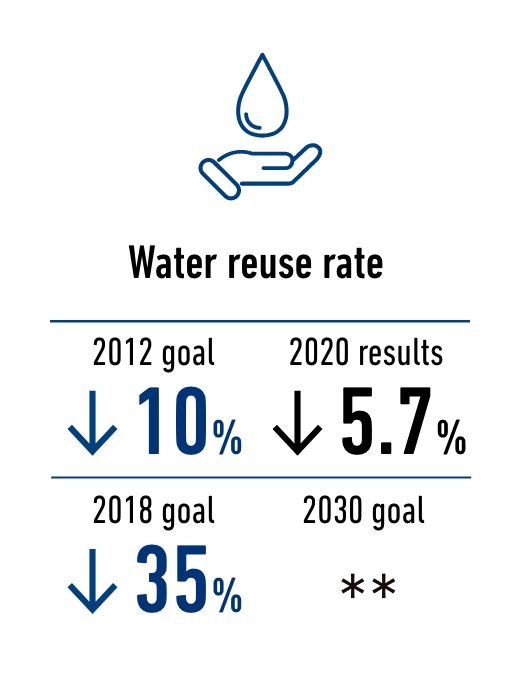

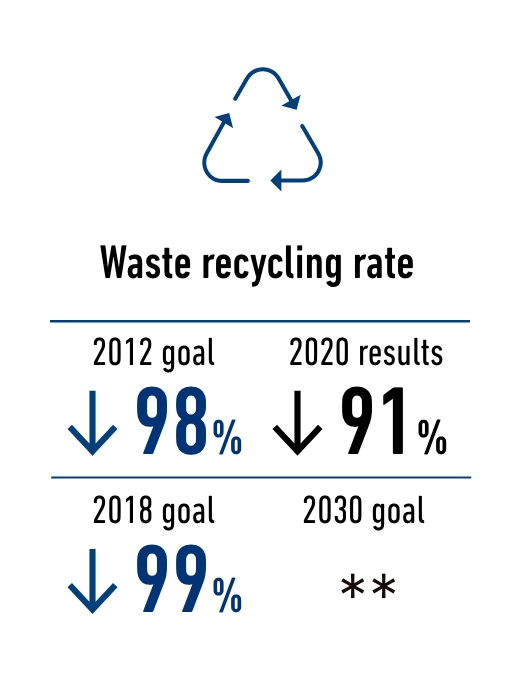

Environmental goals