Continuing the tradition of kasuri

by overcoming tough times

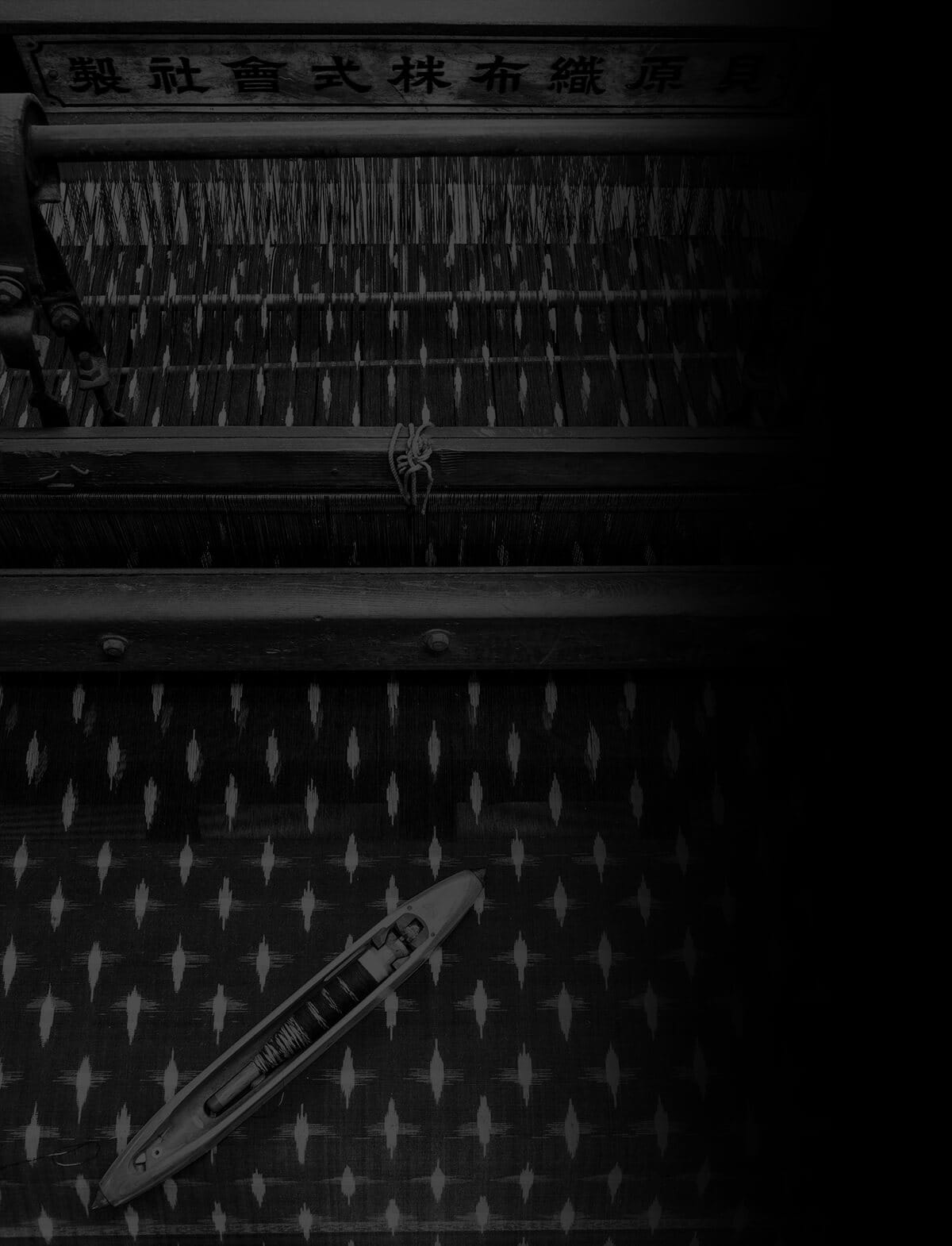

Fukuyama City in Hiroshima Prefecture, where Kaihara maintains its Head Office and Factory, has flourished as a Bingo kasuri production area for a long time ago. Kaihara was founded in 1893 as a weaver of handwoven authentic indigo-dyed kasuri textile. The founder Sukejiro Kaihara who had learned the manufacturing technology of kasuri, used the logo of “㋜ (marusu)” in the beginning. In those days, in the midst of the Sino-Japanese and Russo-Japanese Wars, times were difficult, but Kaihara’s business steadily grew, and in ten years after its foundation, it had grown to 30 employees and manufactured 5,000 tans (bolts) of kasuri each year. In 1920, Sukejiro’s son Satoru succeeded his father in the family business, and set upon expanding the business.

However, due to the outbreak of the Pacific War in 1941, the distribution of yarn was halted and threw the company into financial difficulties. Although it rode out the crisis by switching to the production of Bangkok hats and vine ropes for military purposes, the business was in extreme difficulty after the War because of a downturn in demand for kasuri. At its peak, there were about 300 looms in operation, but the number dropped sharply to just 34 looms.

Making high quality products

that are appreciated by people

It was Sadaharu Kaihara, the third generation family successor who was inspired by the crisis for survival. Sadaharu relayed his enthusiasm to employees: “Why don’t we make high quality products with all our heart and soul from the perspective of the wearer?” Employees took up the challenge and worked together to carry out research, and in 1956, succeeded in manufacturing wide kasuri fabric for Western clothing. The elaborately completed 36-inch (90 cm) wide kasuri fabric was highly praised by many companies, attracting a great deal of attention: “It is unbelievable that there is a company producing such an amazing product in the Hiroshima countryside!”

After that, Kaihara teamed up with Dainippon Boseki and started mass production of wide kasuri fabric. Moreover, Kaihara achieved production of the world’s first 36-inch-wide KONII kasuri fabric, a feat that remains a manufacturing milestone in Japanese clothing history. In 1960, production and export of clothing materials called sarongs worn by people from Muslim countries started, and became highly regarded as top-quality products by people throughout the Middle East. Kaihara, once thrown into crisis, was able to overcome difficulties through Sadaharu’s inspiration.

Finding our way toward denim

while inheriting the knowledge and skills of kasuri

Kaihara had steadily recovered its business when in 1967 it was again confronted with crisis. The value of the British pound depreciated sharply as British troops withdrew from Aden in the Middle East, Kaihara’s major export destination. This caused sarong exports to plummet, and earnings slumped to 1/3. The number of employees also fell by half, leaving Sadaharu in distress, but here again a proposal that would prove to be a major turning point was brought about. Weaving companies and clothing manufacturers were asked to apply the technical know-how and skills cultivated in kasuri to make denim fabrics. Around that time, antiwar movements protesting the Vietnam War were gaining steam, and young people around the world had begun to wear jeans as a symbol of peace. At the same time, Japan’s first brand of jeans was also born, and it was predicted that demand for denim would grow in the future. Sadaharu decided to make a major shift in Kaihara’s business from a kasuri manufacturer to a denim fabric manufacturer. This led to the road toward a denim factory.

Bringing Japan’s first rope dyeing machine to completion,

and enabling domestic production

Soon after shifting to the manufacture of denim fabrics, Kaihara was faced with a difficult challenge. While kasuri is manufactured by using the kasezome (skein dyeing) technique of dyeing yarns to the core, the distinctive fading of denim could not be produced with that technique. Having obtained information that yarns were being dyed in rope-like bundles in the US, Sadaharu tackled the challenge of developing a rope dyeing machine by applying the uniquely developed kasuri manufacturing technology called “submerged wringing.” And it took seven months before Japan’s first rope dyeing machine was completed in 1970. A foothold was gained in manufacturing denim fabrics on a full-scale basis.

Shortly after that, orders rushed in from fabric manufacturers and spinning companies. The following year, there was a placement of orders worth about 300,000 pairs of jeans. In addition, taking the opportunity of receiving an order from Levi’s in 1973, Kaihara attracted worldwide attention as a denim fabric manufacturer.

Becoming a truly global company

by building on the old ways of doing things

to create new things

With the success of rope dyeing, Kaihara kicked off the manufacture of domestically produced denim fabrics, and thereafter, continued to aim for further advancement. The nation’s first integrated production system handling all processes of manufacturing denim fabrics was established by completing weaving facilities in 1978, finishing facilities in 1980, and spinning facilities in 1991. At first, people said that entering into other processes was reckless, but this proved indispensable to making high-quality denim fabrics.

Currently, Kaihara maintains four production bases in Hiroshima Prefecture, and a newly established factory in Thailand to manufacture denim fabrics that are equal in quality to domestic products. The domestic market share is approximately 50%, and export destinations number roughly 30 countries. Kaihara’s strength lies in its ability to manufacture through the fusion of old and new techniques, such as making excellent use of legacy shuttle looms while actively introducing state-of-the-art equipment, just as we used resources and accumulated skills cultivated from kasuri in making denim when we first started. While inheriting the traditions and spirit of innovation, Kaihara aims to become a global company.